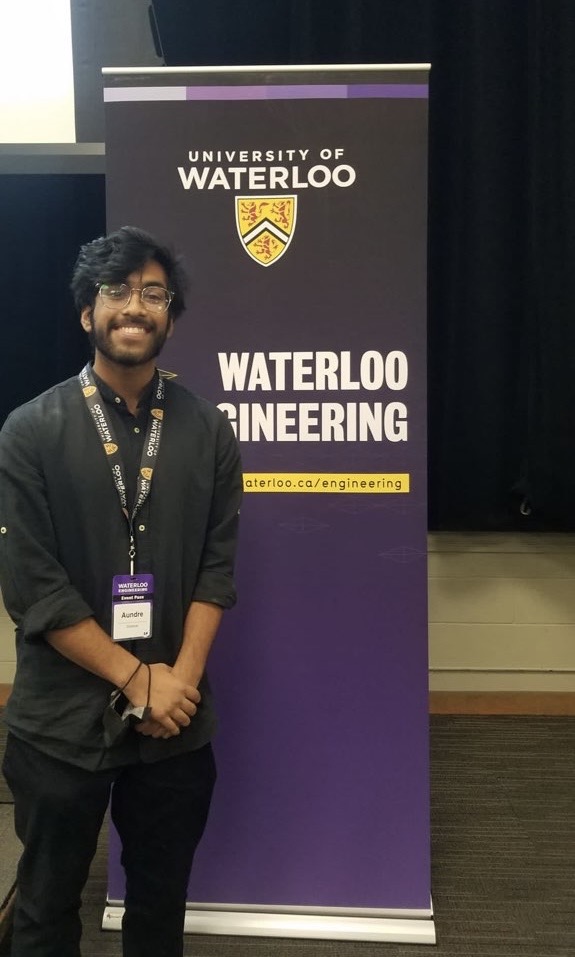

About me

I'm Aundre Jeganathan, a third-year Electrical Engineering student at the University of Waterloo with a passion for robotics, programming, and problem-solving. Specializing in Robotics, I have developed skills in hardware circuitry, embedded programming, and project management, working on projects like a gesture-controlled robot using Raspberry Pi 4 and Arduino. Alongside my technical work, I have actively contributed to my community as a member of the Teen Council and a volunteer at SAAAC (South Asian Autism Awareness Centre), where I lead activities for individuals with autism. I am driven by the desire to apply my engineering skills to create innovative solutions and make a meaningful impact in both technology and the community.

What i'm doing

-

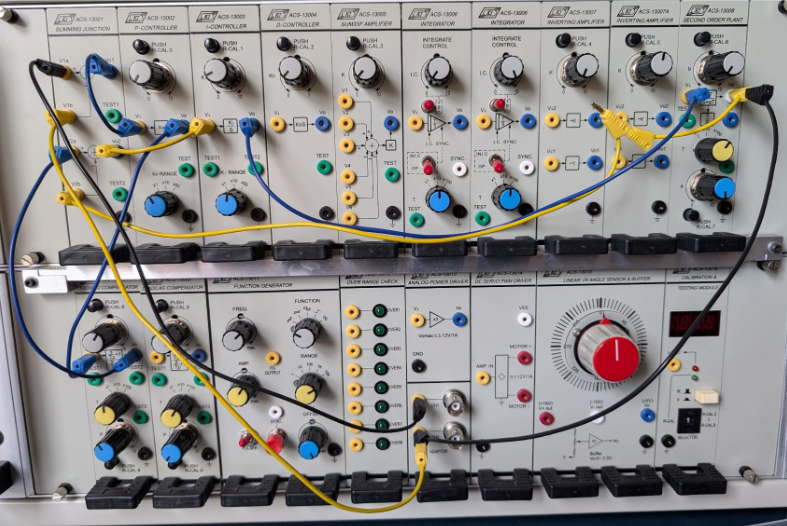

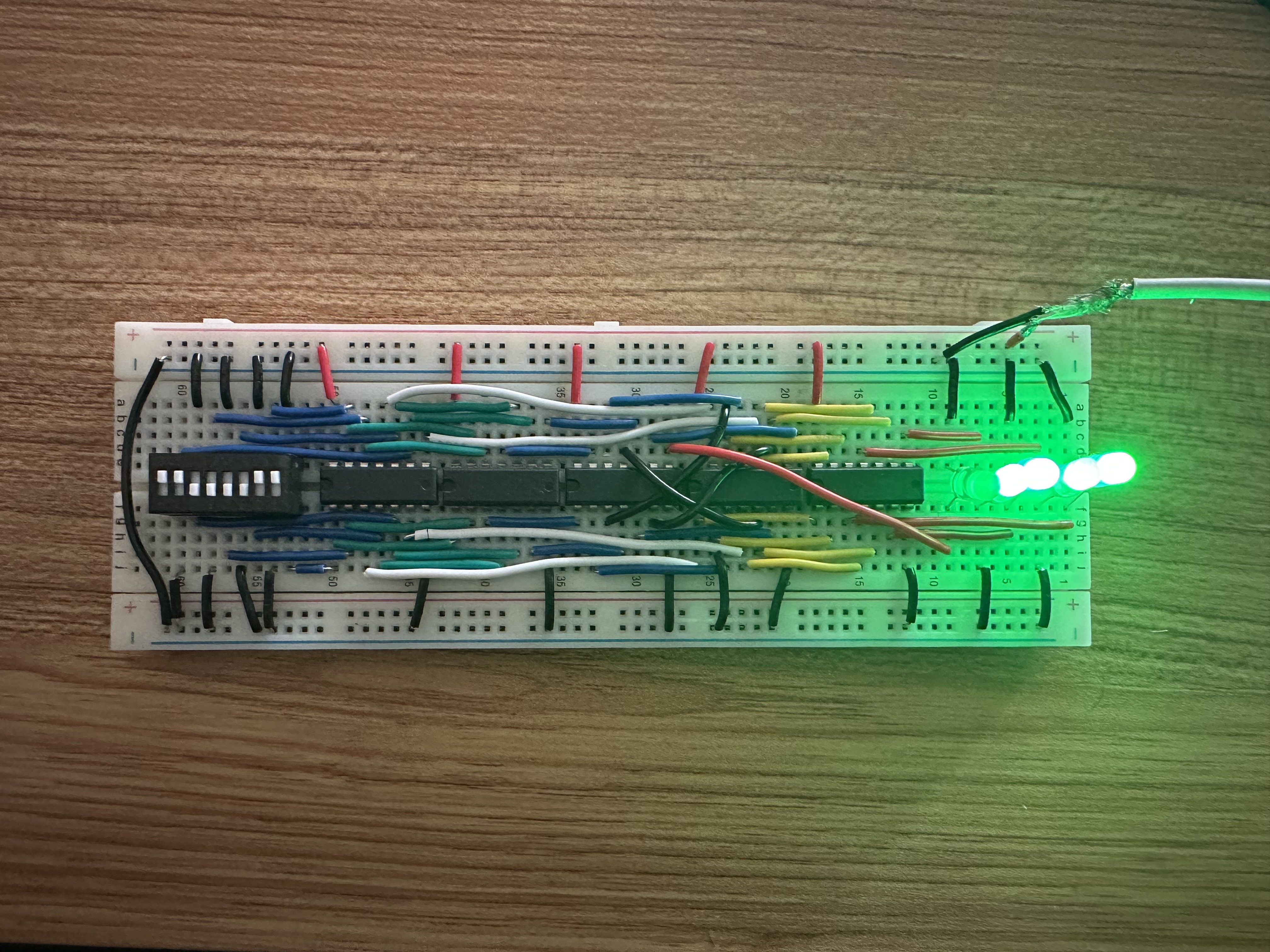

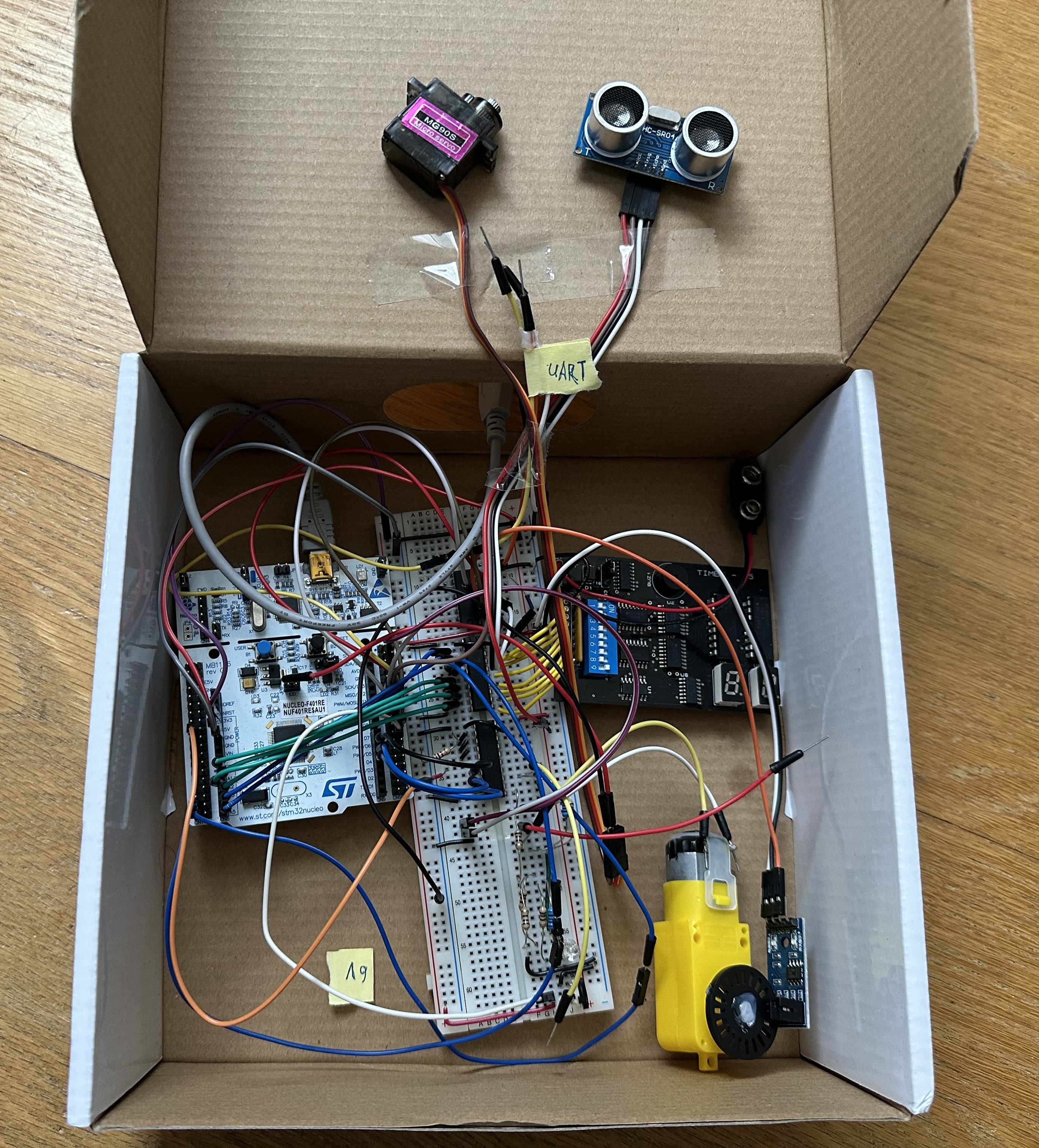

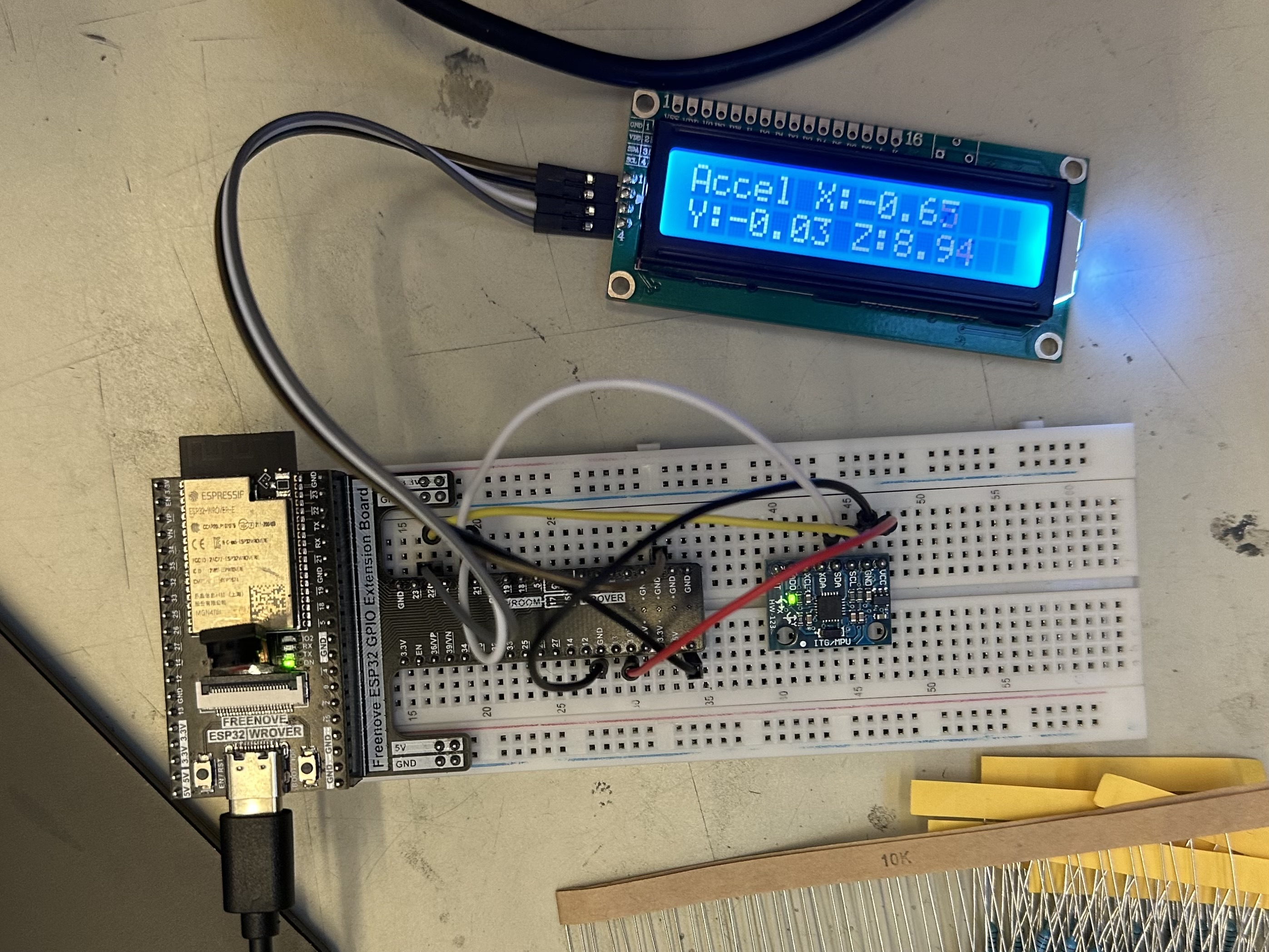

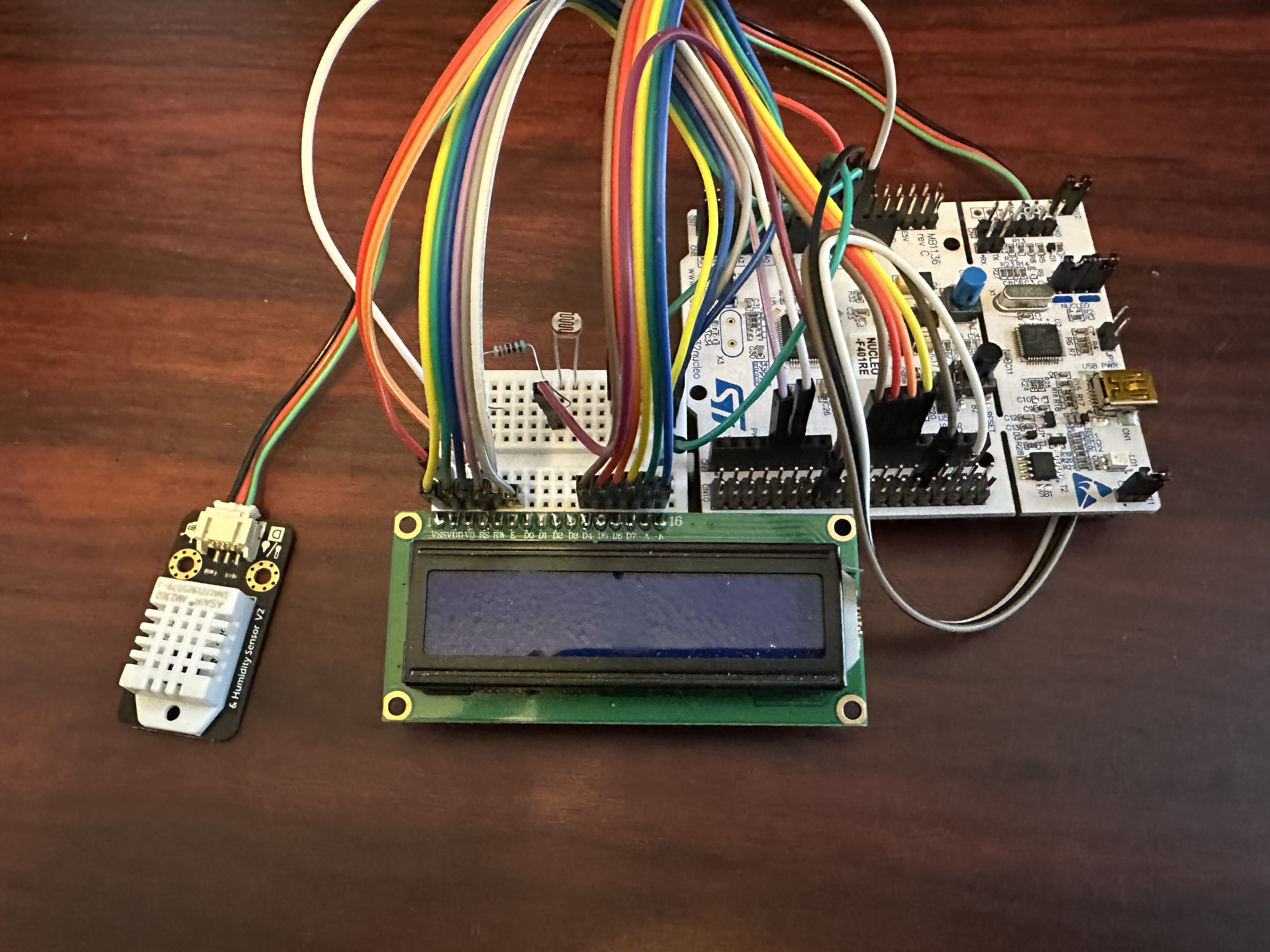

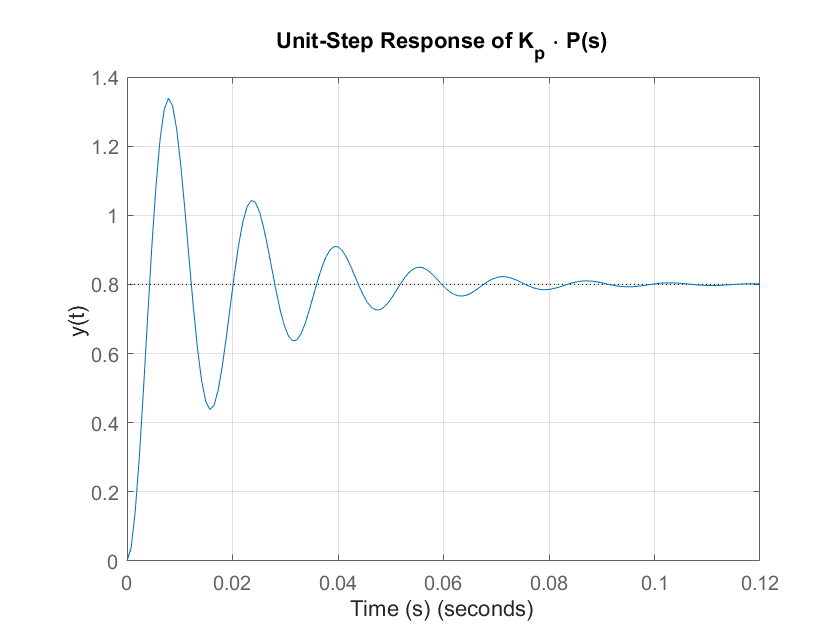

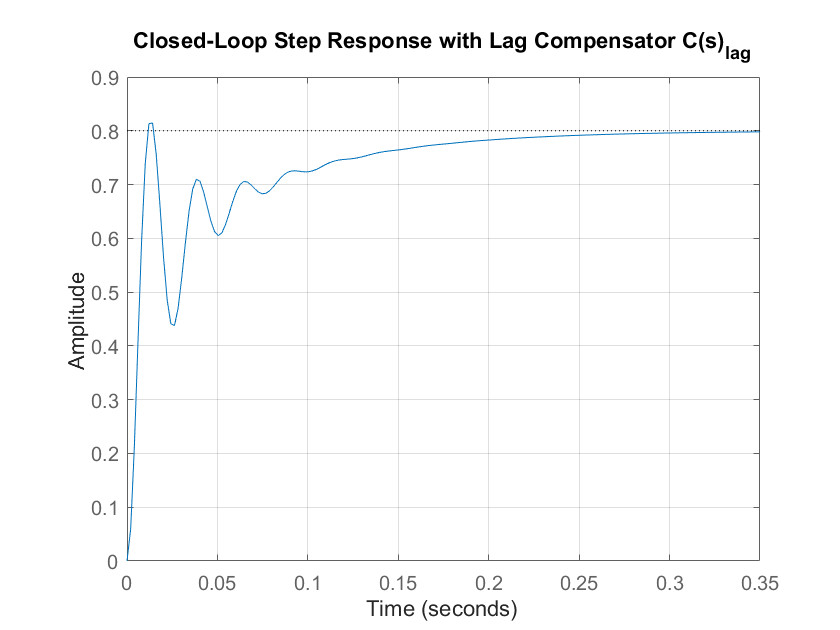

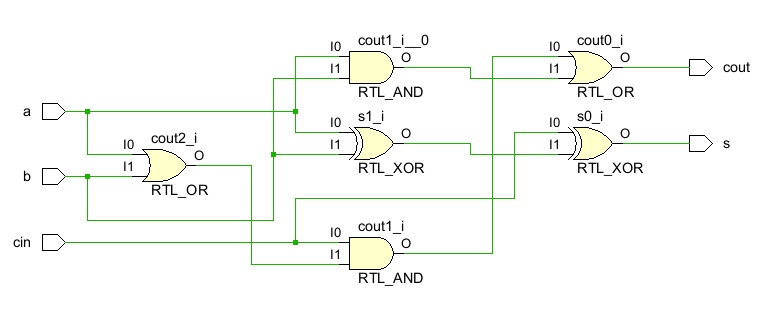

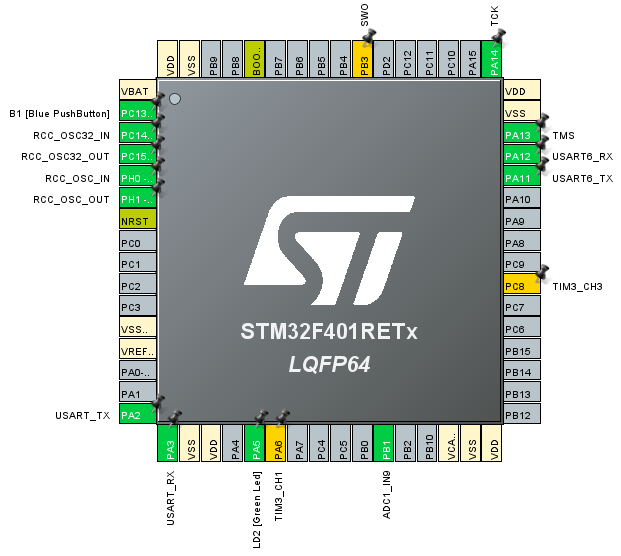

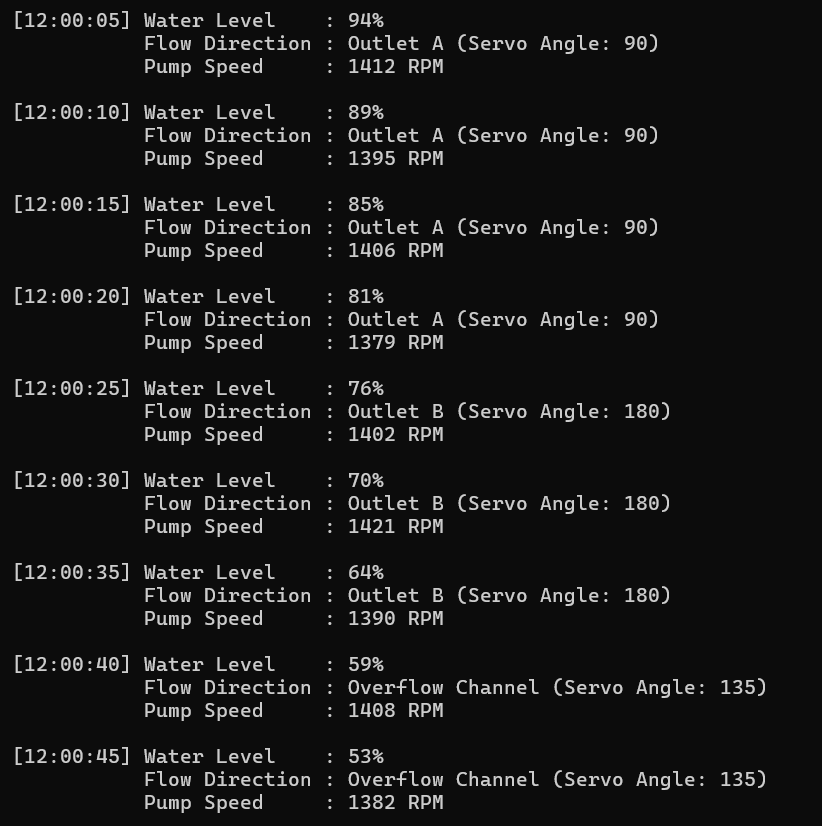

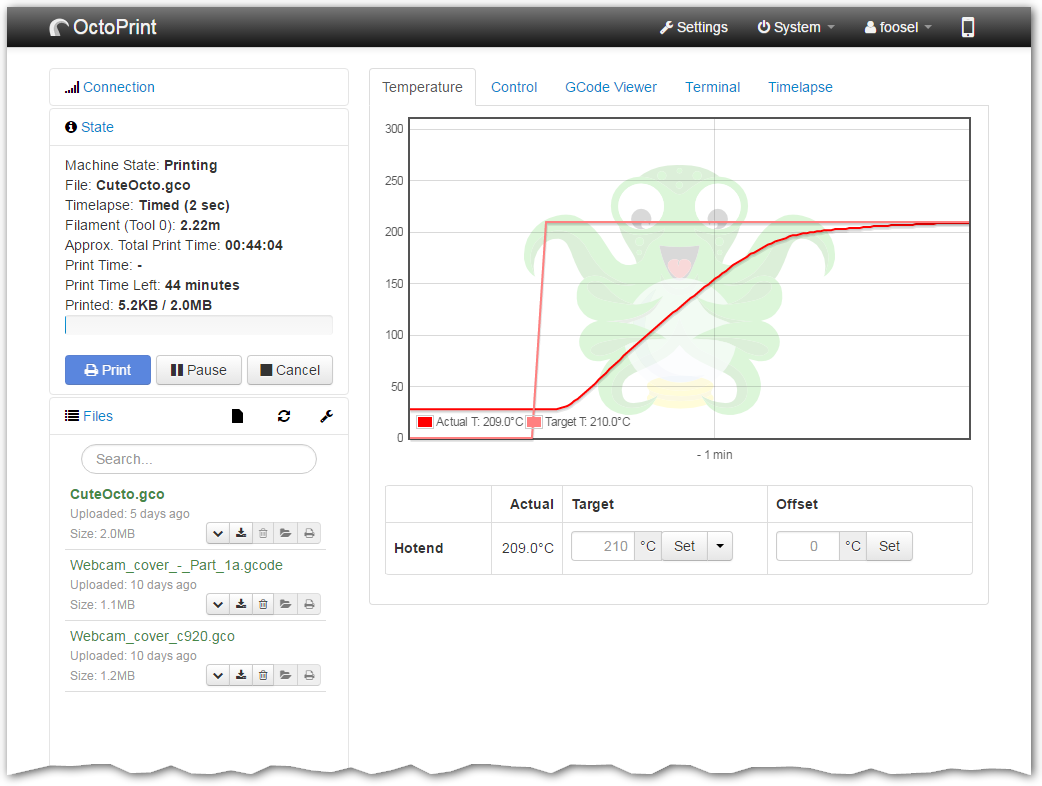

Embedded Systems

Experience writing high-quality code for various microcontrollers.

-

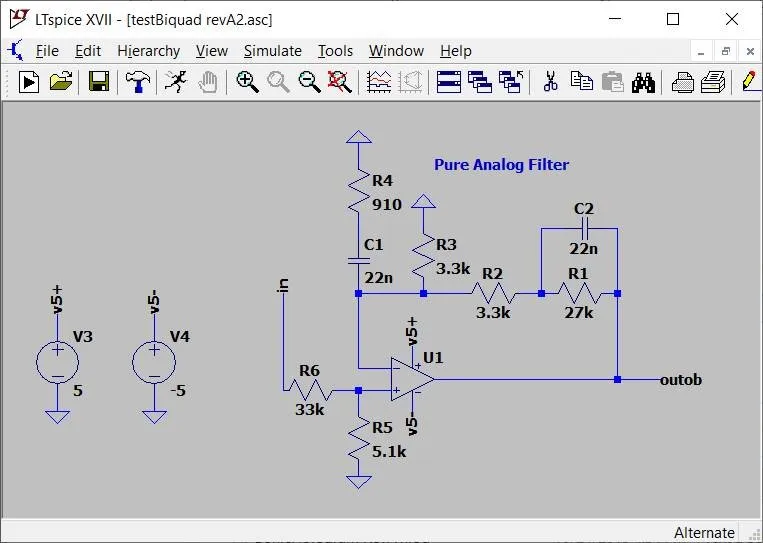

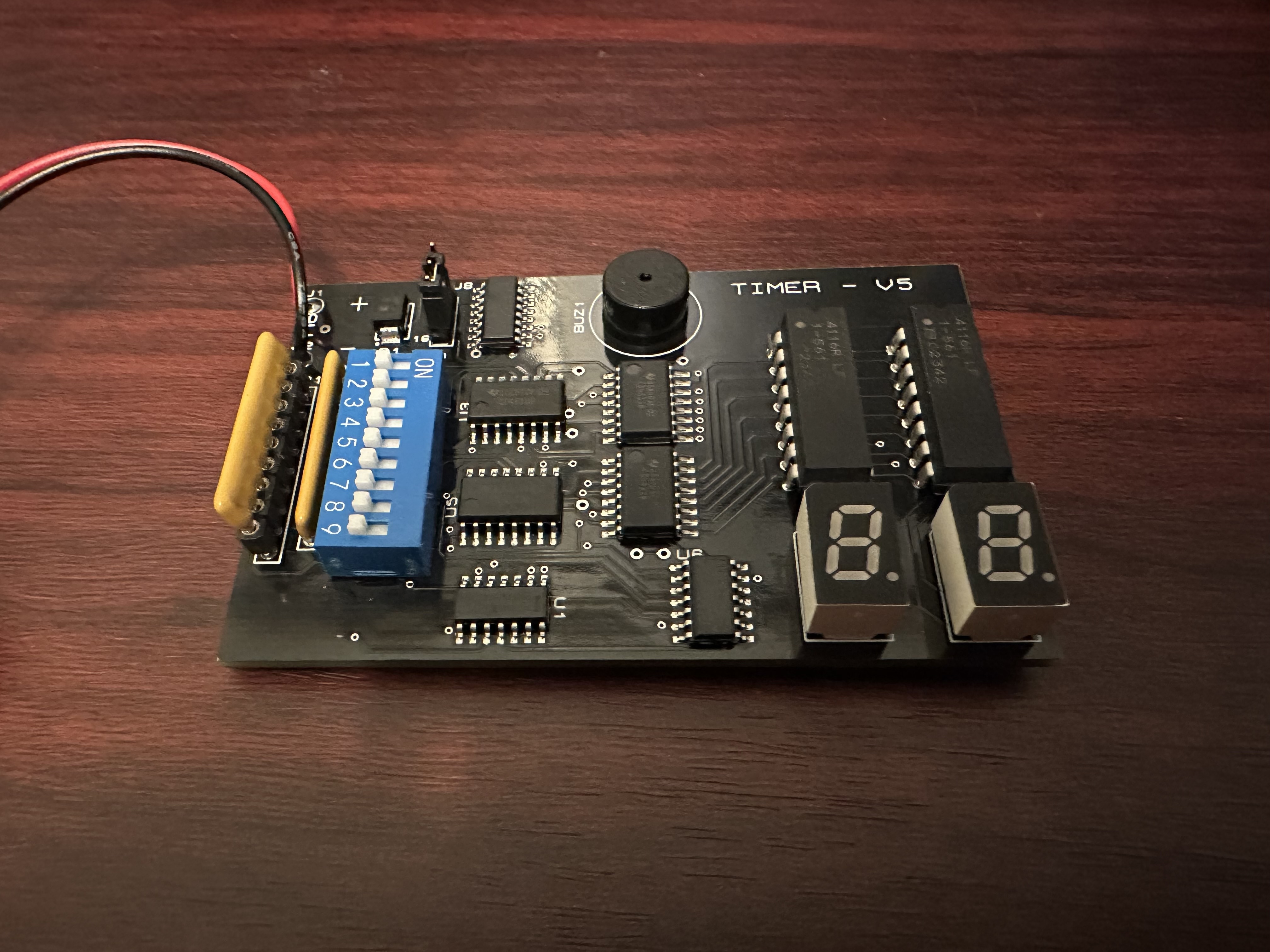

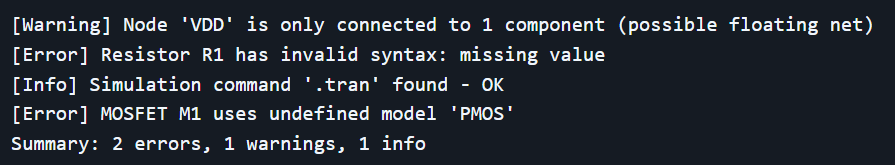

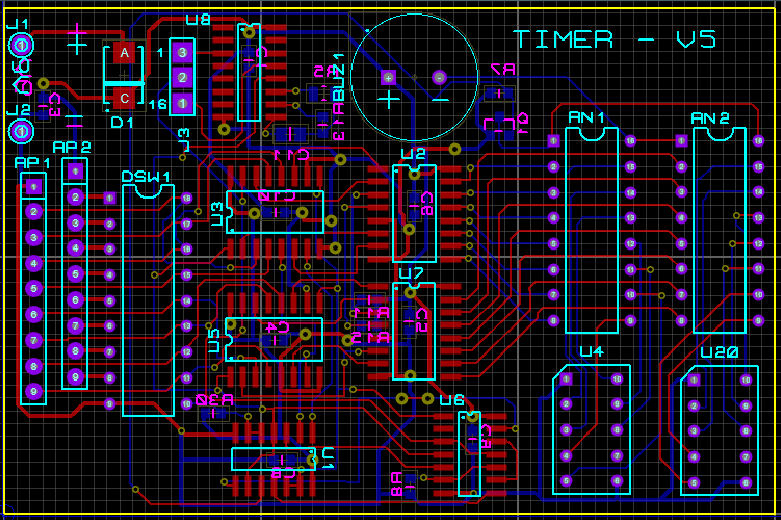

Electronics

Proficient skills in designing, wiring and soldering circuits and PCBs.

-

Software

Adept in programming, showcasing mastery across various languages.

-

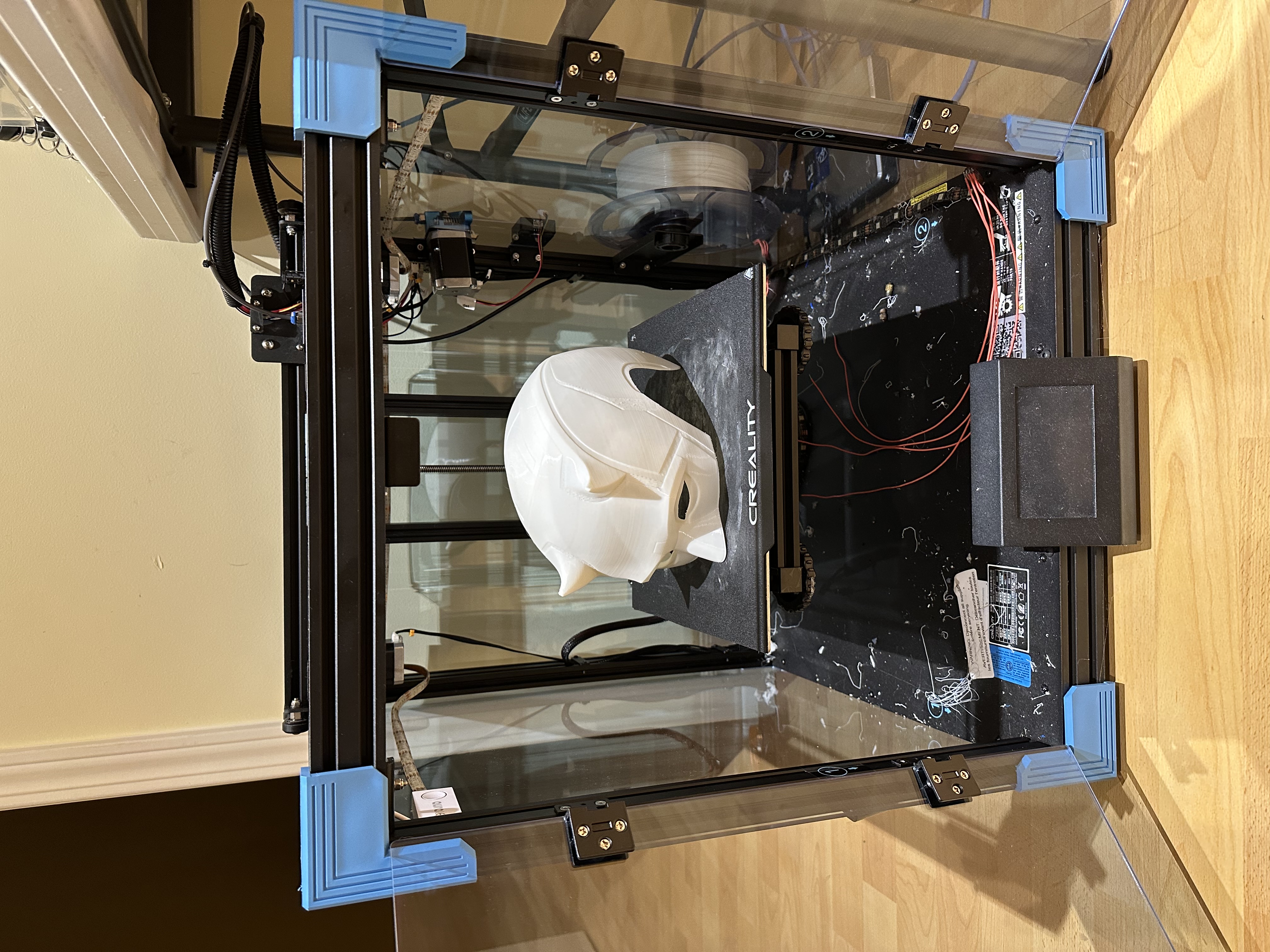

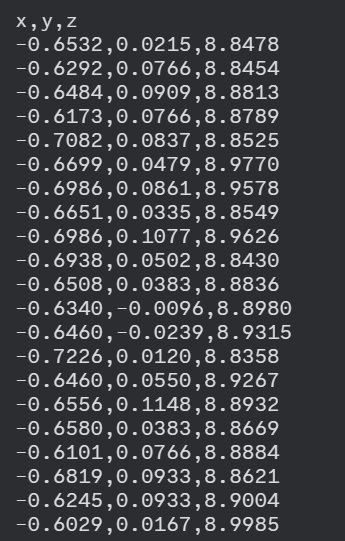

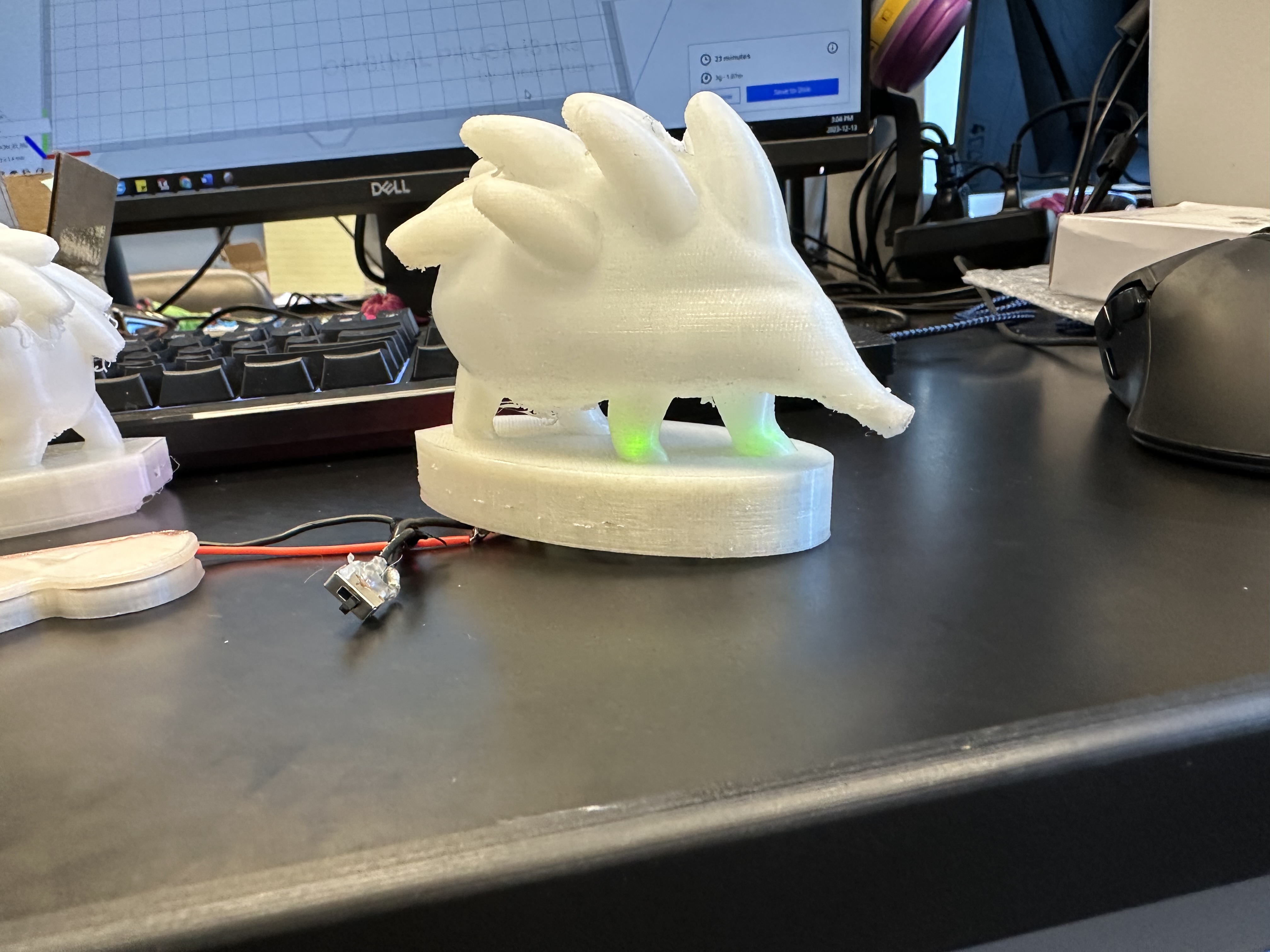

Mechatronics

Aquired skills with robotics, mechanics, and sensor technology.